Water management

strategy for the finalization of the groundwater rebound at the Ronneburg

uranium mine, Germany

Michael Paul & Michael Hüttl

WISMUT GmbH,

Jagdschänkenstraße 29, D-09117 Chemnitz

1. Introduction

WISMUT GmbH is carrying out the closure of the

entire East German uranium mining industry. The remediation program is one of

the largest mine closure projects in the world. Among the former mining sites

the Ronneburg mining district which produced from both underground and open pit

operations was the most important one with a production of 111 kt U between

1951 and 1990. The Ronneburg deposit is situated in a series of blackshales,

limestones and

magmatites of Ordovician to Devonian age (Lange & Freyhoff 1991). By the

end of 1990 the complex underground mine consisted of 14 mine fields with 40

shafts and about 3000 km of mine workings.

Since the late 1960s the dominant mining technology was cut and fill mining, whereas in the early mining period of the 1950s and 1960s various caving methods were practiced. The overall volume of the underground mine amounted to about 68 Mm3 of which about 44 Mm3 were backfilled.

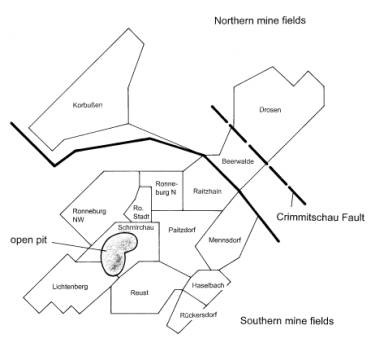

Flooding of the underground mine is taking place within two hydraulically isolated areas (see Fig.1): (1) Mine fields south of the federal motorway A 4, (2) Mine fields north of the motorway A 4. Both parts of the mine are hydraulically separated.

Fully fledged flooding of the southern mine fields was initiated at the turn of 1997/1998 after a four-year-permitting and preparation phase. Flooding of the northern mine fields started in 2000 (Paul et al. 1998, 2002, Gatzweiler et al. 2002).

Since the mine is completely backfilled in its uppermost 100 meters and no dewatering adits are available the flood waters are expected to eventually discharge “naturally” into local receiving streams. As the mine water quality in the southern mine fields does not allow untreated discharge, the mine water has to be catched and treated. Due to the orographic and geologic conditions such discharges can arise at the earliest at a flooding level of approx. 240 m above sea level. By September 2004 the water levels in the southern and northern mine fields have reached levels of approx. 205 m and 215 m above sea level, respectively. The flooding operation is expected to complete between 2006 and 2008 by reaching a quasi-steady state. First mine water discharge in valley regions could appear in 2005/2006. Thus a water management system had to be designed to avoid an intolerable impact of the mine closure on the environment with special reference to ground and surface waters.

The paper

describes the water management system with its individual components as

well as the intended mode of operation.

Figure 1

Schematics of the

Ronneburg mine site showing the different mine fields

2. Overall system for water management and water treatment

Due to the geographical situation, the size of the mine area and the preferred flooding strategy the water management system for the southern mine fields consists of installations for water collection, transport, treatment and discharge. The overall system can be subdivided into the following parts:

- Deep

well (No. 1) with pump and pipeline for water supply (length approx. 0.5

km) to the treatment plant,

- Groundwater

collection system in the Gessental valley with pumping station and

pipeline (length approx. 3.8 km) for water supply to the water treatment

plant,

- Water

treatment plant (WTP) Ronneburg,

- Pipeline

for water discharge from the treatment plant into a borehole to the mine

(on the area of the WTP),

5.

Pipeline for water discharge into the

Wipsegraben creek (length approx. 2.7 km).

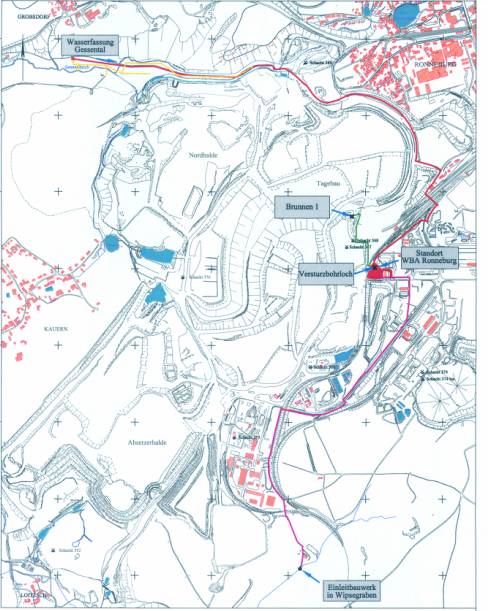

Figure 2 Overview of the water management system at Ronneburg

Central component of the overall system represented in fig. 2 is the Ronneburg water treatment plant (WTP). The completion of the WTP in December 2001 was the basic precondition to actively control the groundwater rebound and to prevent a hazardous impact to the environment at the end of mine flooding. To meet these requirements, the WTP was designed for a capacity of 450 m³/h. The plant operates according to the HDS technology, the main treatment purpose is the separation of heavy metals and radionuclides from the mine water (Hüttl & Paul 2004).

The water supply from the mine to the WTP is realized both from (1) a well (Well No. 1) which is connected to the underground galleries, and (2) from the central pumping station of the water drainage system in the Gessental valley which is expected to be the main water discharge area of the contaminated groundwater after the groundwater rebound has finished.

Well No. 1 was was finished in December 2001. During the following start-up and operational tests in 2002/ 2003 the water to be treated was pumped out of the mine using this well. According to the predictions the water drainage system in the Gessental valley is needed at the earliest in 2005, therefore its completion was scheduled for mid 2004.

Both opportunities of water supply are necessary. On the one hand there must be the possibility to influence the flood water rise in the mine directly. On the other hand the water level in the mine shall be adjusted without any water supply directly from the open mine voids in order to reach a high inundation level, to minimize the catchment area of the mine, to limit the thickness of the unsaturated zone which is subject to further acid generation and finally to lower operational costs for water management, including water treatment and sludge disposal. After reaching the final flooding level the water will be collected in the Gessental water collection system only and supplied to the WTP. At present it is assumed that the water treatment must be carried out over a period of 15 to 25 years without any interruption.

3. Deep Well No. 1

Deep well No. 1 was established still before

closing the mine, the borehole was drilled from the underground galleries to

the surface. The location of the well was carefully selected to guarantee a

sufficient hydraulic connection to the whole underground mine. The well is connected to two main

levels of the mine. It is supported by a 600 mm high-grade steel pipe. The well

was equipped with a submerged pump, which was laid out for a pumping rate of

160 m³/h to 600 m³/h over a maximum height of 200 m. The pump is a five-step,

submersible pump with an electrical demand of 400 kW. It’s maximum diameter is

0.5 m, the overall length is 5.8 m.

The control of

the submerged motor-driven pump, in particular the adjustment of the pumping

rate, is realized by a frequency inverter, which is placed in a container (see

fig.3).

Figure 3 Wellhead of Well No. 1 with inserted pump, control and safety devices

During the trial runs of the Ronneburg WTP in 2002 and 2003 the mine water to be treated was pumped from Well No. 1 for approx. 1 year. Over the entire time period all the well installations as well as the installed pumping equipment proved to be very reliable.

During the 2003

operational test phase the groundwater recharge to the mine could be estimated

to be about 280 m³/h, so that the designed capacity of the pump was confirmed

in practice. Monitoring results from some 20 groundwater wells have shown that

the mine water withdrawal using well No. 1 effectively and instantaneously

affects the groundwater rebound within the entire southern mine fields (about

45 km2).

4 Water

drainage system in the Gessental Valley

Preceding studies confirmed that the Gessental valley will be the location where rising mine water levels could firstly exceed ground elevations. This valley is located west of the city of Ronneburg, close to the former Lichtenberg open pit. It stretches about 2000 m in east – west direction at elevations from 250 down to 235 m a.s.l. and is about 50 m wide in its upper part. The most permeable country rocks, namely Silurian and Ordovician formations, which were also subjected to mining, crop out in the Gessen valley at their lowest elevation.

Based on a detailed hydrogeological investigation

a water drainage system in the valley area was established in 2003/04

(Unland et al. 2002). The drainage system was designed for a maximum flow rate of 330 m³/h. It

consists of (see fig.4):

- 1640

m strings of combined drainage and collection pipes,

- burried

vertical drains where hydrogeological conditions facilitate these well type

installations,

- local

filter blankets augmented with drainage pipes and with a top seal of local

loamy sediments,

- a

groundwater well directly connected to the uppermost mine level, which can

be used to directly control the minewater head,

- a

pumping station in the valley-deepest as well as

- the

water supply pipe to the Ronneburg WTP.

Figure 4 Water drainage system in the Gessental Valley – schematic representation

The line drainage is accessible over 23 manholes, in order to carry out maintenance and control measures as well as for possible system extensions. Further external water drainage subsystems close to the backfilled former Lichtenberg open pit will be merged into the collecting line.

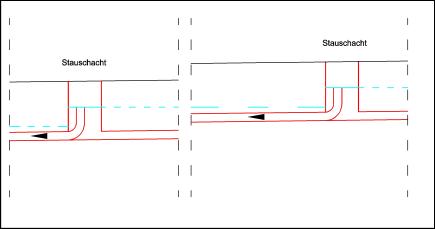

The overflow system is shown schematically in

Fig. 5. The system is simple and will need some attention only in the initial

stages of the groundwater rebound for proper balancing.

The pumping system at the end of the gravity line consists of 3 identical pumps designed to switch regularly between stand-by and operation mode. The maximum total pumping capacity installed right from the beginning will be 400 m³/h. The pump house is designed for quick machinery changes in case of repair and maintenance.

Figure 5 Scheme of overflow system preventing air from entering the collector pipes.

The system is designed for continuous flow through and does not provide for any significant storage. For cases of emergency and failures of the pumping system an automatic overflow into a 1,600 m³ capacity storage basin is provided.

It is expected, that the collected groundwater will contain high amounts of Fe(II). To prevent oxygen entry which would course ochre formation all manholes have been provided with gas tight covers and will be positively pressurised by a nitrogen atmosphere.

After successful

tests of the water drainage system it was taken over by WISMUT GmbH in June

2004. According to the present flooding rate the commissioning of the system is

expected for 2006.

Literature

Gatzweiler R, Jakubick AT, Paul M, Schreyer J, Meyer J (2002): Flooding the WISMUT mines - Learning by doing or applying a comprehensive systematic approach?- Proceedings of the International Conference Uranium Mining and Hydrogeology III and the International Mine Water Association Symposium, Freiberg, Germany, 15-21 September 2002, Springer 2002, pp. 745-754

Hüttl M, Paul M

(2004): WBA Ronneburg – Wasserbehandlung nach dem HDS-Verfahren – BHT 2004 /

Koll. 8, Freiberg, Juni 2004

Paul M, Gengnagel M, Vogel D, Kuhn W (2002): Four years of flooding WISMUT’s Ronneburg uranium mine – a status report. In: Uranium in the Aquatic Environment.- Proceedings of the International Conference Uranium Mining and Hydrogeology III and the International Mine Water Association Symposium, Freiberg, Germany, 15-21 September 2002, Springer 2002, pp. 775-784

Unland W, Eckart M, Paul M, Kuhn W, Ostermann R (2002): Groundwater rebound compatible with the aquatic environment – technical solutions at WISMUT’s Ronneburg mine - Proceedings of the International Conference Uranium Mining and Hydrogeology III and the International Mine Water Association Symposium, Freiberg, Germany, 15-21 September 2002, Springer 2002, pp. 667-676